Extrusora Monocapa vs Multicapa: ¿Cuál es Mejor para su Producción?

Extrusora Monocapa v

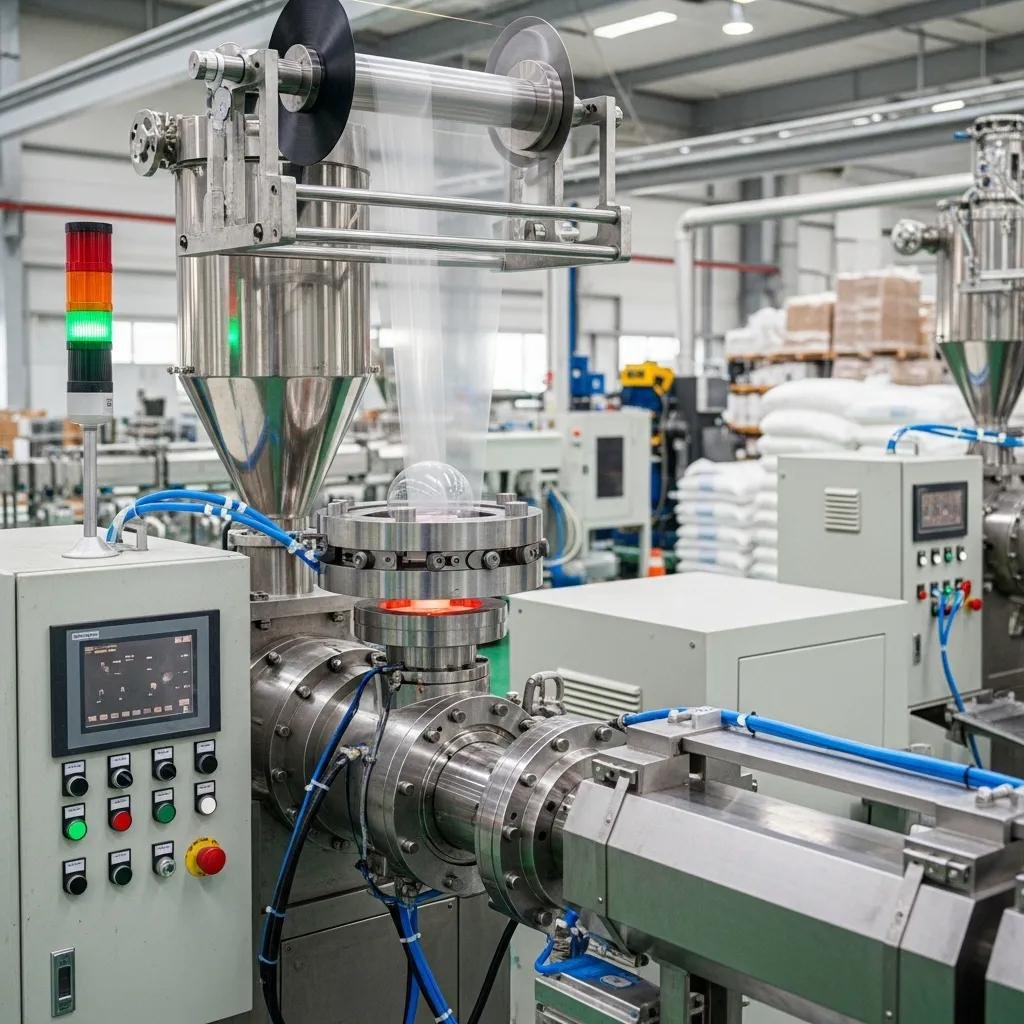

Blown film extrusion is a critical process in the manufacturing of plastic films, widely used in packaging and other applications. Understanding the essential components of a blown film extruder is vital for optimizing production efficiency and film quality. This comprehensive guide will delve into the key parts of a blown film extruder, their functions, and how they contribute to the overall operation of the film blowing machine. Many manufacturers face challenges in achieving consistent film quality and operational efficiency. By exploring the intricacies of each component, this article aims to provide solutions and insights into improving the blown film extrusion process. We will cover the main parts of the extruder, the role of the cooling system, the function of the collapsing frame, the winding unit, control systems, and troubleshooting common issues.

Indeed, the intricate nature of blown film extrusion, involving multiple stages from melting to winding, underscores the need for comprehensive understanding and evaluation.

Blown Film Extrusion Process & Evaluation Factors

Blown film is extruded as a continuous tube which is air cooled, collapsed, and wound onto a roll as a double layer of film. There are many factors that affect blown film extrusion. Therefore, using expert system to evaluate blown film extrusion processes becomes an attractive subject.

Expert system for blown film extrusion, 1991

The blown film extruder consists of several key components that work together to produce high-quality plastic films. Understanding these parts is essential for anyone involved in the manufacturing process.

The extruder unit is the heart of the blown film extrusion process. The screw is responsible for transporting, melting, and mixing the polymer, while the barrel provides the necessary heat for melting. The hopper feeds the raw material into the extruder, ensuring a continuous supply. Each component plays a vital role in achieving the desired melt temperature and viscosity, which are critical for producing high-quality films.

The die head is a crucial component that shapes the molten polymer into a tubular film bubble. Different types of die heads, such as spiral mandrel and spider die heads, are used depending on the desired film characteristics. The die head’s design influences the film’s thickness and width, directly impacting the final product’s quality. Proper adjustment of the die head is essential for achieving uniform film thickness and optimal performance.

The air ring and cooling system play a significant role in determining the quality of the blown film. They are responsible for cooling the film bubble as it exits the die head, which is essential for maintaining its shape and preventing defects.

The air ring provides a controlled flow of air around the film bubble, facilitating rapid cooling. This cooling process stabilizes the bubble and prevents it from collapsing. The temperature and flow rate control within the air ring are critical, as they affect the film’s mechanical properties and overall quality.

Internal bubble cooling (IBC) is another method used to enhance film quality. This technique involves circulating cooling air inside the bubble, which helps maintain a consistent temperature throughout the film. Frost line control is essential for ensuring that the film maintains its shape and does not develop defects such as uneven thickness or wrinkles. The frost line is the visible line on the bubble where the polymer solidifies, and its position is a key indicator of cooling efficiency.

Further emphasizing the importance of precise bubble management, research highlights how monitoring the film bubble’s shape and contour can provide critical insights for advanced process control.

Blown Film Quality: Bubble Detection & Process Monitoring

In blown film extrusion, film properties are predominantly influenced within the bubble formation zone, where the molten polymer expands from a thick-walled tube to a solid thin-walled sensitive film bubble. The characteristic bubble shape or contour, respectively, represents the state of balance resulting from all underlying process conditions and therefore its inline detection offers potential for an advanced process monitoring.

Sensor-based process monitoring by inline bubble detection in blown film extrusion, 2023

The collapsing frame and nip rollers are essential for processing the film after it has been formed. They ensure that the film is flattened and wound correctly for storage and further processing.

The collapsing frame flattens the tubular film bubble as it exits the air ring, allowing for precise control over the lay-flat width. This control is crucial for ensuring that the film meets specific dimensional requirements for various applications. Techniques such as adjusting the angle and position of the collapsing frame can help achieve the desired width.

Nip rollers play a vital role in managing film tension during the winding process. Proper tension control is essential for preventing defects and ensuring consistent output. Techniques such as adjusting roller speed and pressure can help maintain the desired tension throughout the production process.

The winding unit is responsible for collecting the finished film into rolls, which are then prepared for shipment or further processing. This unit is critical for maintaining the integrity of the film during storage.

Automatic winder systems enhance the efficiency of the winding process by ensuring consistent roll integrity. These systems can adjust tension and speed automatically, reducing the risk of defects in the final product. Proper roll integrity is essential for preventing issues such as telescoping, wrinkles, or loose winding during transportation and storage.

Effective tension control is crucial for optimizing roll diameter. By managing the tension during the winding process, manufacturers can ensure that the rolls are uniform and meet specific requirements. Techniques such as adjusting the winding speed and tension settings can help achieve optimal roll diameter and prevent film damage.

Control systems and automation are increasingly important in modern blown film extrusion processes. They enhance efficiency and ensure consistent quality throughout production.

AI-driven process optimization allows for real-time monitoring of various parameters, such as temperature, pressure, and film thickness. This technology enables manufacturers to make adjustments on-the-fly, improving overall efficiency and product quality. By leveraging data analytics, companies can identify trends and optimize their processes for better performance.

Integrating sensors into the extrusion process provides valuable data that can be used to enhance control. Sensors can monitor critical parameters, such as melt temperature, pressure, bubble diameter, and film thickness, ensuring that the process remains within optimal ranges. This integration helps prevent defects and improves overall film quality.

Troubleshooting common issues in blown film extruders is essential for maintaining production efficiency and film quality. Identifying and addressing these problems can prevent costly downtime and defects.

Common film defects, such as wrinkles and uneven thickness, can arise from various factors, including improper cooling, unstable bubble formation, and tension management. Identifying the root cause of these defects is crucial for implementing effective solutions. Techniques such as adjusting cooling rates, air ring settings, and tension controls can help resolve these issues.

Regular maintenance of extruder components is essential for ensuring their longevity and optimal performance. Implementing a maintenance schedule that includes routine inspections and cleaning can help prevent issues before they arise. Best practices such as lubricating moving parts, checking for wear, and ensuring proper alignment can significantly extend the lifespan of the equipment.

Different winding systems deliver distinct benefits through specific mechanisms.

| Winding System | Feature | Benefit |

|---|---|---|

| Automatic Winder | Adjustable tension | Consistent roll integrity |

| Manual Winder | Operator-controlled | Flexibility in production |

| Semi-Automatic Winder | Combination of both | Balance of efficiency and control |

This comparison demonstrates how different winding systems can impact the efficiency and quality of the final product.

Kingdom Machine CO.,LTD es el fabricante y proveedor de equipos de toda la planta para hacer películas de plástico y bolsas de plástico, incluida Extrusora De Pelicula Sopladora,Maquina Para Hacer Bolsas,Impresora Flexografica,Maquina Huecograbado,Extrusora Reciclaje,Maquina para Stretch Film,Máquina Poli Burbuja.

Movil/Whatsapp:008613088651008