Componentes Esenciales de una Extrusora de Film Soplado

Essential Components

In the world of plastic film production, the choice between monolayer and multilayer extruders can significantly impact the quality and cost-effectiveness of the final product. This comprehensive guide will delve into the characteristics, benefits, and applications of both types of extruders, helping you make an informed decision for your production needs. Understanding the differences between a monolayer extruder and a multilayer extruder is crucial for optimizing production efficiency and product quality. Many manufacturers face challenges in selecting the right extruder that meets their specific requirements. This article will explore the mechanics, advantages, and applications of each extruder type, as well as the latest industry trends and decision-making tools to aid in your selection process.

A monolayer extruder is a type of machine used in the production of plastic films, characterized by its single-layer output. This design simplifies the extrusion process, making it a popular choice for various applications. The primary benefits of monolayer extruders include cost-effectiveness, operational simplicity, and suitability for a wide range of materials. These extruders are particularly advantageous for manufacturers looking to produce standard plastic films without the complexities associated with multilayer systems.

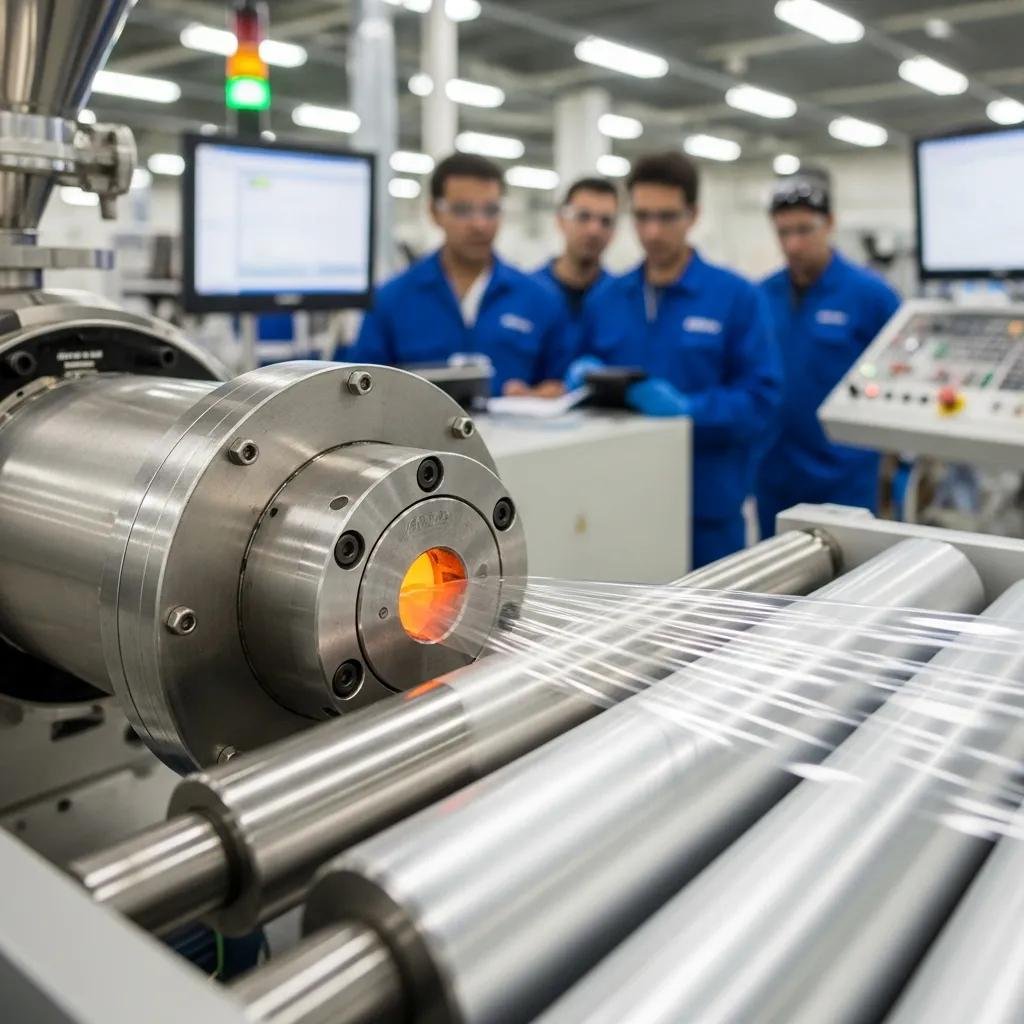

Monolayer extruders operate by melting plastic pellets and forcing the molten material through a die to form a continuous film. The process involves several key components, including the hopper, barrel, screw, and die. The screw plays a crucial role in mixing and conveying the material, ensuring uniform melting and consistent film thickness. The output characteristics of monolayer films typically include good clarity and strength, making them suitable for various packaging applications.

Monolayer extruders are often more cost-effective than their multilayer counterparts due to lower initial investment and operational costs. The simplicity of the design reduces maintenance requirements and operational complexity, allowing manufacturers to achieve higher efficiency. For instance, the initial investment for a monolayer extruder can be significantly lower, making it an attractive option for small to medium-sized businesses. Additionally, the straightforward operation of these machines enables quicker training for operators, further enhancing productivity.

A multilayer extruder is designed to produce films with multiple layers, allowing for enhanced functionality and performance. This type of extruder utilizes co-extrusion technology, which enables the simultaneous processing of different materials to create films with specific properties. The advantages of multilayer extruders include improved barrier properties, mechanical strength, and the ability to incorporate recycled materials into the production process.

Co-extrusion technology enhances multilayer film functionality by allowing the combination of various polymers, each contributing unique properties to the final product. For example, one layer may provide excellent moisture barrier properties, while another layer offers strength and durability. This technology enables manufacturers to tailor films for specific applications, such as food packaging, where barrier properties are critical for preserving freshness.

Multilayer extruders produce films with superior barrier properties compared to monolayer films. The combination of different materials in multilayer films can significantly reduce gas and moisture permeability, making them ideal for packaging sensitive products. Additionally, multilayer films often exhibit enhanced mechanical strength, which is essential for applications requiring durability and resistance to punctures or tears. This makes multilayer extruders particularly valuable in industries such as food and pharmaceuticals.

When comparing monolayer and multilayer extruders, several factors come into play, including film properties, production costs, and overall efficiency. Monolayer films typically offer good clarity and strength, while multilayer films excel in barrier properties and customization options. Understanding these differences is crucial for manufacturers aiming to optimize their production processes.

Monolayer films generally have uniform thickness but may lack the advanced barrier properties found in multilayer films. In contrast, multilayer films can achieve varying thicknesses across different layers, allowing for tailored performance. This customization is particularly beneficial in applications where specific barrier requirements must be met, such as in food packaging, where moisture and oxygen barriers are critical.

The initial investment for monolayer extruders is typically lower than that for multilayer extruders, making them more accessible for smaller operations. However, multilayer extruders can offer a higher return on investment (ROI) in the long run due to their ability to produce higher-value films with enhanced properties. Operational costs may also vary, with multilayer systems potentially incurring higher maintenance costs due to their complexity. Manufacturers must weigh these factors when deciding which extruder type aligns best with their production goals.

Choosing the right extruder depends on the specific applications and material flexibility required for production. Monolayer extruders are well-suited for standard packaging applications, while multilayer extruders excel in producing specialized films that require advanced properties.

Monolayer extruders are commonly used in applications such as general-purpose packaging films, shopping bags, and agricultural films. Their simplicity and cost-effectiveness make them ideal for manufacturers focusing on high-volume production of standard products. The ability to produce clear and strong films is particularly advantageous in the packaging industry, where visual appeal and durability are essential.

Multilayer extruders offer significant advantages in supporting recycled materials and material customization. The ability to incorporate recycled polymers into multilayer films not only enhances sustainability but also allows manufacturers to create products tailored to specific market demands. This flexibility is increasingly important as industries move towards more sustainable practices and seek to reduce their environmental impact.

The extrusion industry is evolving rapidly, with advancements in technology and materials shaping the future of production. Key trends include the integration of AI-driven systems and a focus on energy efficiency, which are transforming how extruders operate.

AI-driven systems are enhancing extruder performance by optimizing production processes and reducing waste. These systems can analyze real-time data to adjust parameters for maximum efficiency, leading to improved product quality and reduced operational costs. Additionally, energy-efficient designs are becoming increasingly important as manufacturers seek to minimize their carbon footprint and comply with environmental regulations.

Post-consumer recycled (PCR) materials are playing a crucial role in modern extrusion processes, as manufacturers strive to incorporate sustainable practices into their operations. The use of PCR materials not only reduces waste but also meets the growing consumer demand for environmentally friendly products. As sustainability becomes a priority, the ability to produce high-quality films from recycled materials will be a key differentiator in the market.

Selecting the right extruder involves considering various factors, including production volume, material requirements, and desired film properties. Utilizing decision-making tools can simplify this process and ensure that manufacturers make informed choices.

Several factors should influence your choice between monolayer and multilayer extruders, including the specific applications you intend to target, the materials you plan to use, and your budget constraints. Understanding the unique benefits of each extruder type will help you align your production capabilities with market demands.

A decision matrix or flowchart can serve as a valuable tool in the extruder selection process. By outlining the key factors and criteria relevant to your production needs, these tools can help visualize the decision-making process and guide you toward the most suitable extruder type. This structured approach ensures that all critical aspects are considered, leading to a more informed and strategic choice.

Further research highlights the importance of structured decision-making models in optimizing polymer extrusion processes.

Decision-Making Model for Polymer Extrusion Optimization

This paper presents further developments to the NN-DM method to find a model in a polymer extrusion process. The form of the DM’s interaction, the domain assignment, the ranking process, and the performance assessment are adapted to a real context of a multi-objective optimization problem followed by a design decision.

A Model for a Human Decision-Maker in a Polymer Extrusion Process, RHC Takahashi, 2015

| Extruder Type | Key Features | Ideal Applications | Cost Considerations |

|---|---|---|---|

| Monolayer | Simplicity, Cost-effective | General packaging, bags | Lower initial investment |

| Multilayer | Enhanced properties, Customization | Food packaging, specialized films | Higher initial investment, potential for better ROI |

Kingdom Machine CO.,LTD es el fabricante y proveedor de equipos de toda la planta para hacer películas de plástico y bolsas de plástico, incluida Extrusora De Pelicula Sopladora,Maquina Para Hacer Bolsas,Impresora Flexografica,Maquina Huecograbado,Extrusora Reciclaje,Maquina para Stretch Film,Máquina Poli Burbuja.

Movil/Whatsapp:008613088651008

impresora de bolsas plasticas, extrusora de pelicula, confeccionadora de plastico, máquina para hacer bolsas tipo camisetas, máquina para hacer bolsas

Las máquinas para fabricar bolsas de plástico son fundamentales en la industria del embalaje, ofreciendo soluciones eficientes y sostenibles. Con el aumento de la demanda de productos biodegradables, los fabricantes están innovando para crear máquinas que no solo produzcan bolsas de alta calidad, sino que también sean respetuosas con el medio ambiente.

Por ejemplo, las extrusoras de película soplada de última generación permiten la producción de bolsas con materiales reciclados, contribuyendo a la economía circular. Estas máquinas están diseñadas para optimizar el uso de recursos y minimizar el desperdicio, asegurando que las empresas puedan cumplir con las normativas ambientales actuales.

El uso de máquinas que producen bolsas biodegradables ofrece múltiples beneficios tanto para el medio ambiente como para las empresas. Estas máquinas permiten la creación de productos que se descomponen naturalmente, reduciendo la contaminación y el impacto ambiental de los plásticos convencionales.

Además, las empresas que adoptan estas tecnologías pueden mejorar su imagen de marca al alinearse con las expectativas de los consumidores que valoran la sostenibilidad. Al invertir en maquinaria de producción biodegradable, las empresas no solo cumplen con las regulaciones, sino que también pueden acceder a nuevos mercados que priorizan productos ecológicos.

La industria de la fabricación de bolsas de plástico está en constante evolución, impulsada por la innovación tecnológica y las cambiantes demandas del mercado. Las tendencias actuales incluyen la automatización de procesos, el uso de inteligencia artificial para optimizar la producción y la integración de tecnologías de reciclaje en las líneas de producción.

Un ejemplo notable es la implementación de sistemas de control de calidad automatizados que garantizan que cada bolsa producida cumpla con los estándares de calidad más altos. Estas tendencias no solo mejoran la eficiencia operativa, sino que también ayudan a las empresas a reducir costos y aumentar la satisfacción del cliente.

Seleccionar la máquina adecuada para fabricar bolsas de plástico es un paso crucial para cualquier negocio en esta industria. Factores como el tipo de bolsa que se desea producir, el volumen de producción y el presupuesto son determinantes en la elección del equipo más adecuado.

Es recomendable realizar un análisis exhaustivo de las especificaciones técnicas y las capacidades de producción de cada máquina. Además, consultar con proveedores y expertos en el campo puede proporcionar información valiosa que facilite la toma de decisiones, asegurando que la inversión realizada cumpla con las expectativas de rendimiento y durabilidad.